Udine, Italy, Oct. 7, 2022 /PRNewswire/ — LimaCorporate proudly announces the FDA approval of a new shoulder platform focused on versatility and Operating Room efficiency. For the first time in the history of LimaCorporate, both the glenoid baseplate and the humeral stem are fully 3D-printed, leveraging the long legacy in additive manufacturing. This novel implant system takes advantage of the patented Trabecular Titanium (TT) technology, aiming to guarantee a strong primary fixation and a proven secondary bone ingrowth.

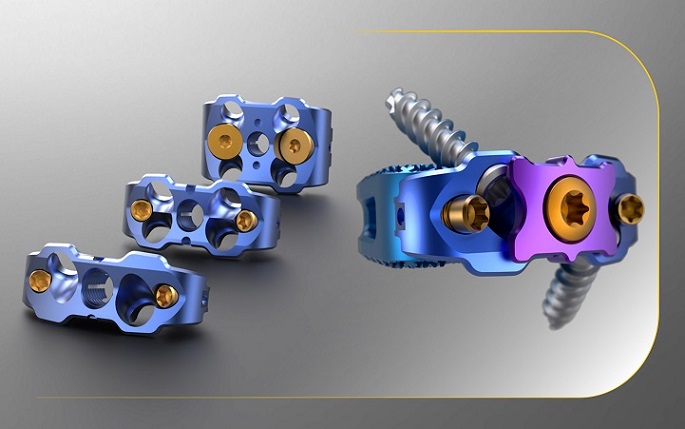

The PRIMA system consists of a novel 3D-printed convertible short stem and a fully 3D-printed glenoid replacement for Reverse Shoulder Arthroplasty.

PRIMA Short Stem is a new addition to the LimaCorporate Shoulder family to satisfy a drive towards greater efficiency in and out of the Operating Room, with its bone preserving fully convertible design allowing simple exchange from anatomic to reverse configuration.

PRIMA TT Glenoid was designed with the ambitious goal of empowering surgeons with a complete solution suitable to solve a wide range of glenoid replacement cases in Reverse Shoulder Arthroplasty. The user can easily move between baseplate designs to address different pathologies from simple primary to complex clinical cases.

Aware that intraoperative experience is one of the major factors influencing surgeons’ practice, the entire development process has been driven by the overarching goal of providing a streamlined surgical technique and instrumentation to support the future users with focus on efficiency and reproducibility.

Massimo Calafiore LimaCorporate CEO stated “Today’s FDA approval for PRIMA TT Glenoid represents an exciting opportunity to accelerate our market growth in key regions. The new PRIMA shoulder platform will support our surgeons to bring the emotion of motion to even more patients!”.

About Trabecular Titanium (TT)

LimaCorporate has been pioneering 3D printing in orthopedics. The 1000 square meters Research & Innovation Center is located in the company’s headquarters in San Daniele, Italy, and fuels major innovation combining raw materials and digital technologies to create 3D printed orthopedic implants.

Trabecular Titanium (TT) is the patented result of LimaCorporate’s research. This lightweight biomaterial, that is characterized by a unique net geometric structure, is used extensively in reconstructive orthopedics to support surgeons in joint replacement surgery.

TT components are built using Electron Beam Melting (EBM) technology, a high-energy focused beam that melts metal powdered layers forming Trabecular Titanium, which can only be generated using LimaCorporate’s proprietary 3D printing technology.

About LimaCorporate

LimaCorporate is a global orthopedic company, focused on digital innovation and patient-tailored hardware, which advances patient-centred care. Its pioneering technological solutions are developed to empower surgeons, and to improve patient outcomes from joint replacement surgery. Its primary focus is on providing reconstructive and custom-made orthopedic solutions to surgeons, enabling them to improve the quality of life of patients by restoring the joy of movement.

Headquartered in Italy, the company operates directly in over 20 countries around the world. LimaCorporate offers products ranging from large joint revision and primary implants, to complete extremities solutions, including fixation.

For additional information on the Company, please visit www.limacorporate.com

Limacorporate spa

Via Nazionale, 52

33038 Villanova di San Daniele

Udine – Italy

T: +39 0432 945511

E.: info@limacorporate.com; press@limacorporate.com

Logo – https://mma.prnewswire.com/media/997351/LimaCorporate_Logo.jpg

SOURCE Limacorporate S.p.A