Alfonso Bone Simulator dramatically shortens the implant design process, setting a new “gold standard” for implant testing.

Hong Kong SAR, 24 August 2021 /OrthoSpineNews/ – Lifespans today announced that it will launch its new cloud-based simulation system for orthopaedic implant manufacturers – Alfonso: The future of implant testing – at the upcoming American Academy of Orthopedic Surgeons (AAOS) congress from 31st August to 3rd September in San Diego.

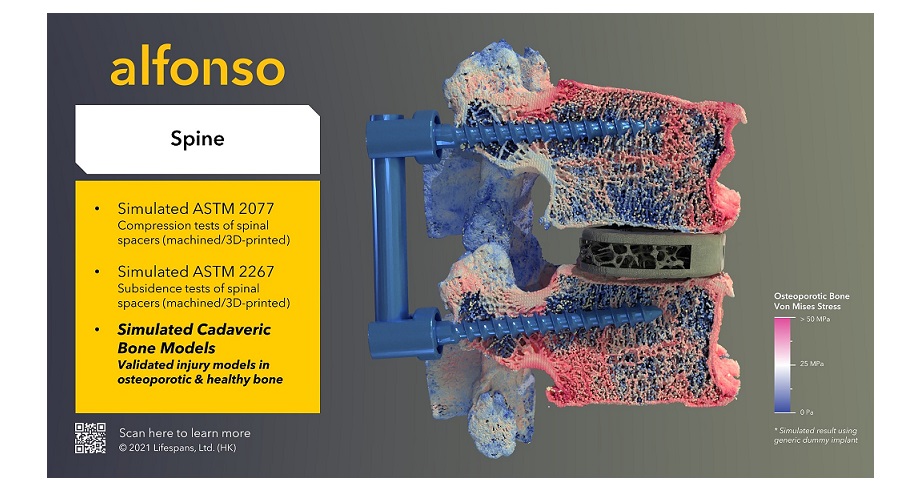

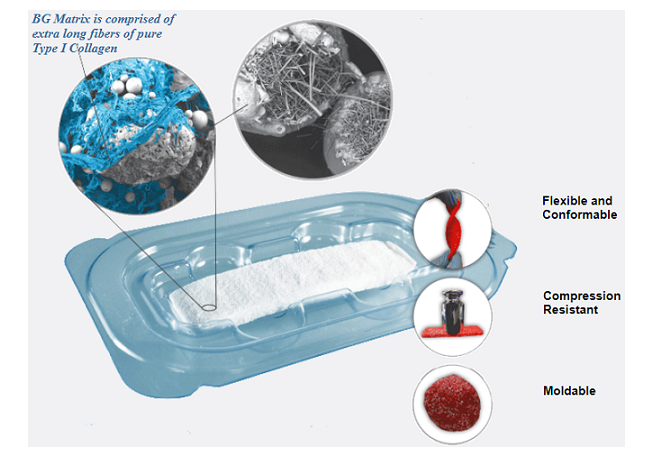

The Alfonso bone simulator incorporates a ground-breaking “particle-based” computer model of bone tissue, invented by its team of MIT engineers and world-leading orthopaedic surgeons. With findings published in the Journal of Orthopaedic Research, it is the world’s first simulation system capable of simulating the cracking and crushing of realistic trabecular bone structures – a key missing feature in conventional simulation that has been sought after for decades.

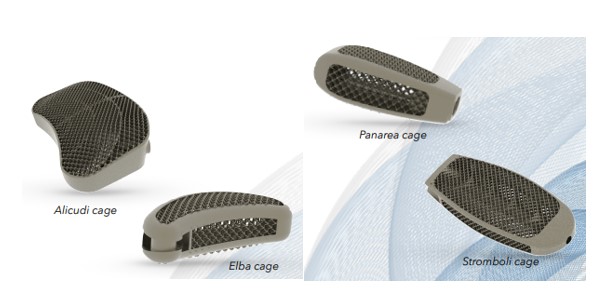

Alfonso can complete same-day testing of joint recon, trauma, and spinal implants and rank their performance against predicates using validated industry-standard ASTM tests (F543, F1264, F2077, F2267, and more). Alfonso also understands the mechanics of cadaveric bone tissue and can easily test implant migration and cut-out in a wide range of validated osteoporotic and healthy adult bone fracture models.

Using Alfonso is a snap – just upload a 3D model to our secure confidential cloud system, select which ASTM or cadaveric models to run, and Alfonsodoes the rest. No prototyping or testing machine booking time needed!

“Lifespans is well-aware that implant manufacturers constantly face time and budget limitations in terms of device prototyping and laboratory testing – especially in the post-Covid global environment. To address this, our engineers dug deep into the underlying theory of bone tissue mechanics to develop what we believe will become the new ‘gold standard’ for pre-clinical safety and efficacy testing of orthopaedic devices in the future,” said Lifespans CEO, Sloan Kulper, Ph.D.

“As an orthopaedic trauma surgeon, using computer simulated bone models is a great shortcut for me to test out my new implant design ideas in days, not weeks”, said A/Prof. Christian Fang, FRCS, from the University of Hong Kong Faculty of Medicine (Dept. of Orthopaedics & Traumatology). “No more pain is needed setting up lengthy hydraulic tests. Now it doesn’t matter that the biomechanics tester in the lab is occupied or out of service, now I can comfortably do my tests from home.”

Paul Higham PhD., Senior Advisor to Lifespan’s Ltd. also said, “with four major implant manufacturers already using Lifespan’s technology in their implant development, Alfonso is on track to become the new standard for pre-clinical testing in the orthopedic devices industry.”

Visitors to AAOS 2021 will be able to see the Alfonso Bone Simulator in action with live demonstrations at their booth #5214 throughout the conference.

Use this link to download hi-res images: https://www.lifespans.net/alfonso

About Lifespans

Founded by MIT engineers, orthopedic surgeons, and industry executives, Lifespans is a spin-off from Asia’s #1 center for orthopaedic surgery – Queen Mary Hospital at the University of Hong Kong. Lifespan’s mission is to create innovative bone implant technology solutions, especially those that improve the quality of life of elderly patients with osteoporosis. More information can be found at: https://www.lifespans.net

Media contact:

Sloan Kulper Ph.D.

Chief Executive Officer

Tel: +1 401 954 9882 (US)

Tel: +852 5411 2339 (HK)

Email: sloan@lifespans.net